System Enhancements

Using our crane expertise and experience, Midwest Overhead Crane can assist in upgrading your equipments current capabilities through the use of modern technology to enhance safety, improve operations, and increase productivity.

VFDs & Radio Controls

Upgrading Radio Controls and Variable Frequency Drive (VFD) to replace your single or double speed motors allows for improvements in productivity, limits wear on your components and improves safety on the floor. Upgrading either or both of these items will allow greater control over load speeds and allow operators to stay out of harms way.

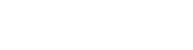

Safety Enhancements

Bad things happen when things crash, collide or fall. Safety upgrades come in many forms from horns for basic safety, catwalks, lights to identify live cranes, load limiters to avoid unsafe and costly breakages and anti collision systems all decrease the possibility of having an incident on a plant floor.

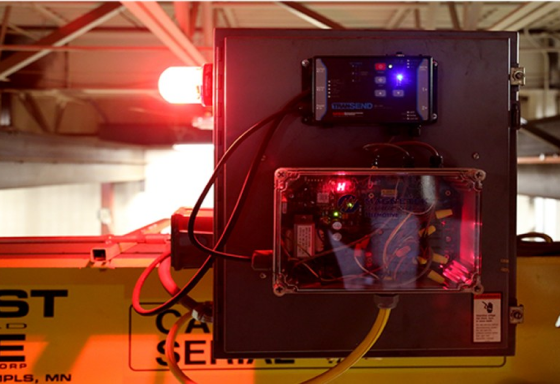

Automation

Depending on the application, automation systems can incorporate a variety of motion control products and sensor systems to designate locations where a crane is programmed to operate and can be added to existing crane controls or incorporated on new installations.

Lights & Work Lighting

Lights to identify when a crane is energized and work lighting on or under bridge cranes can improve both safety and performance on the floor. Safety zone lighting for a warning that gets noticed on a productive plant floor.

Powerful Enhancements for Your Crane System

Improving the performance and productivity of all the components, large and small, of your overhead hoists and crane can give a much needed boost to your equipment that is already working hard for you. Through multiple avenues based on your needs, Midwest Overhead Crane can offer:

- Automation and controls to increase productivity and limit liability

- Runway electrification upgrades can help increase the power and consistency throughout the entirety of your system.

- Variable Frequency Drive (VFD) to replace your single or double speed motors allows for improvements in productivity, limits wear on your components and improves safety on the floor.

- Remote controls installation allow for increased safety and control while operating a safe distance away from the load for maximum visual attention.